Creep and Stress Relaxation Test

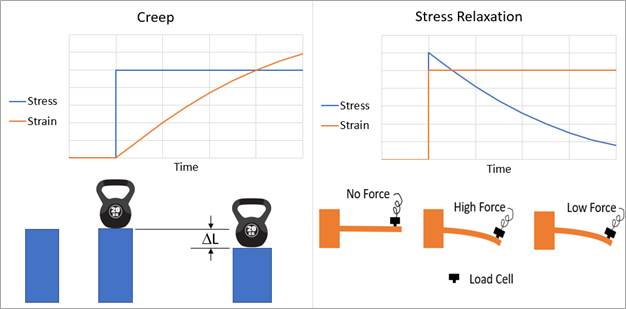

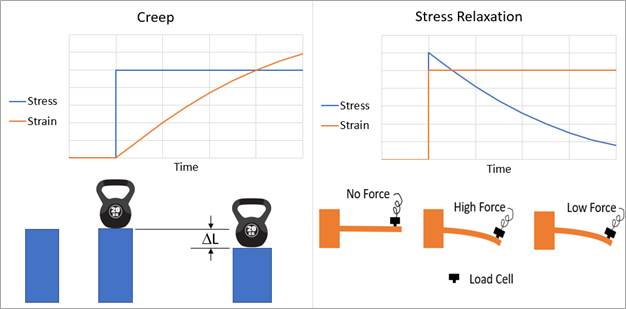

Creep and Stress Relaxation Creep When subjected to load all elastomers exhibit an increasing deformation with time know as creep. 34 Elongation The increase in length of a tensile test piece under stress.

Schematic Of Up Stress Relaxation Down Creep Behavior Download Scientific Diagram

Mechanical testing instruments come in various shapes sizes and capability ranges.

. Natural extracellular matrices ECMs are viscoelastic and exhibit stress relaxation. It can do flexure tensile and compression testing even shear and liquid specimens if desired. Properties that can be measured with a compression test.

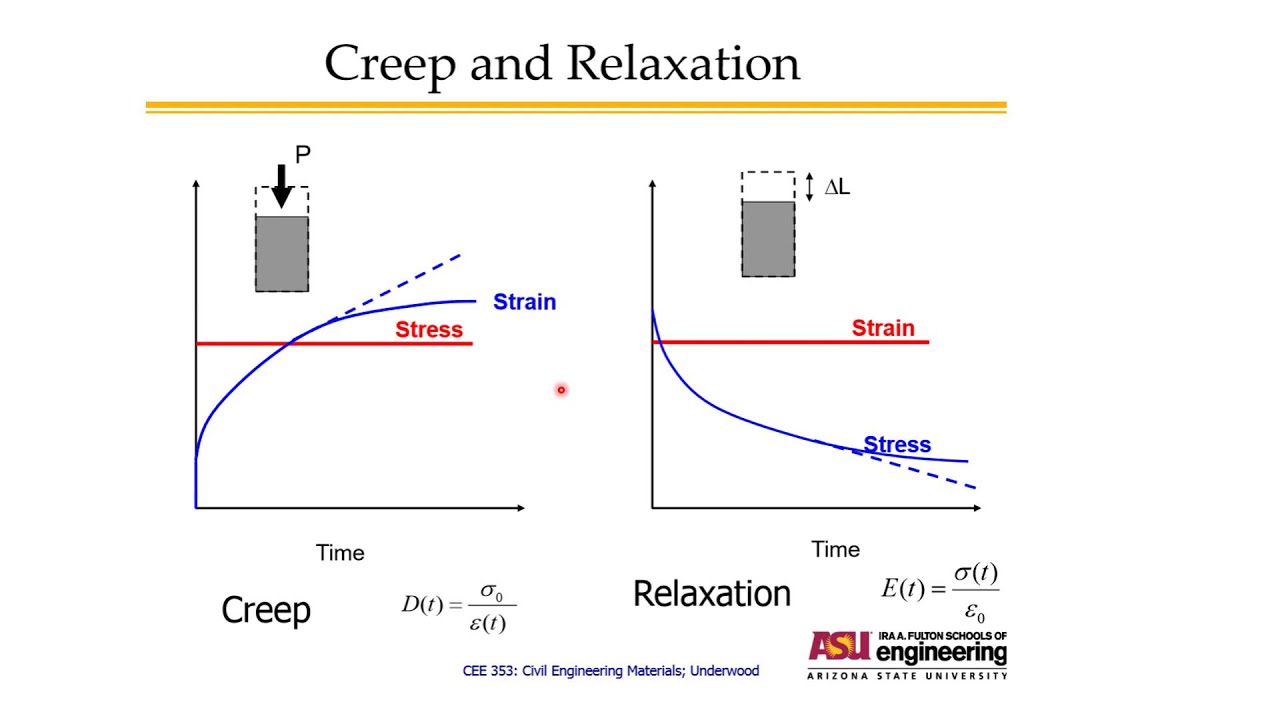

Then the stress relaxes over time due to the viscous effects in the material. In service creep can be minimized by using low working stresses and avoiding high temperatures. Drawing can boost mindfulness.

Tightening the flange after 24 hours will prevent leakage. The maximum load reached in a tensile test of the strand. The closer the test value is to the ideal value the lower the loss of gasket stress of the seal.

33 Coil or Reel One continuous length of strand in the form of a coil or reel. However hydrogels used as synthetic ECMs for three-dimensional 3D culture are typically elastic. The ideal P QR value is 1.

Our company is led by experienced. You Can Pick Your Test Machine in 4 Easy Steps. These analyzers can test higher modulus materials than torsional analyzers.

Thereafter stress relaxation will be. Go beyond conventional DMA testing and program experiments that mimic complex real-world conditions. TA Instruments ElectroForce offers a complete.

Is a manufacturer of mechanical test solutions including universal test machines static dynamic test machines grips fixtures and testing accessories. The instrument can do creep-recovery stressrelaxation and stressstrain experiments. Stress Relaxation Stress Relaxation TTS IsoStrain.

Research from 2018 also suggests mindful coloring activities may help relieve test anxiety a significant source of stress for many students. Compression tests are typically chosen to measure. The traditional pseudo-triaxial stress test is generally used in laboratory tests.

The DMA Unlimited interface delivers the DMA 850s powerful new capability to sequence any and all deformation modes and thermal profiles in a single test. The science of biomechanics helps explain the causes of cell tissue organ and body system disorders and supports clinicians in the diagnosis prognosis and evaluation of treatment methods and. Mindfulness refers to.

We study this problem and identify the two-step mechanism of stress relaxation. Clinical Biomechanics is an international multidisciplinary journal of biomechanics with a focus on medical and clinical applications of new knowledge in the field. Typically either a tensile compressive bulk compression or shear.

Material designers and product manufacturers frequently use these techniques in tandem and therefore need versatile instruments uniquely suited to their specific tests. In a one-dimensional relaxation test the material is subjected to a sudden strain that is kept constant over the duration of the test and the stress is measured over time. For over twenty years TestResources has utilized a modular design approach to create affordable and highly flexible systems to meet a wide range of applications.

Strain Ramp Stress Ramp. In general the stress of a material can be considered as the sum of deviatoric stress and spherical stress Based on the principle of stress composition the above one-dimensional creep model of coal and rock mass is extended to three-dimensional state in this section. Learn about adhesive testing and the material testing solutions we provide within adhesive testing.

This occurs at any stress level and takes place in compression tension and shear loadings and varies for each type of loading. For example a gasket under the pressure of flange bolts will creep resulting in a reduced bolt pressure. Axial analyzers are used for solid or semisolid materials.

Q minL The minimum required line force at ambient temperature for a certain leakage class L when the. Compressibility compactability springiness stress relaxation creep compliance crush strength firmness elastic recovery Youngs Modulus workloaddeflection at rupture maximum load deflection at maximum load stiffness offset yield etc. Stress relaxation is important in applications where the part is subjected to compressive load in contrast to tensile stress.

The initial stress is due to the elastic response of the material. This reduction in load often leads to leakage at the joint. At short time scale relaxation is fast dominated by stress biased thermal.

In case strands the elongation is measured. A measure of creep relaxation at a predefined temperature. It is the ratio between the gasket stress after relaxation and the initial gasket stress.

First start by selecting your frame and actuator Step 1 by system type or test type then complete your system by selecting your controller software Step 2 and accessories Step 3Choose from a wide range of controller software packages grips fixtures chambers video extensometers and more are all designed. The stress relaxation of semi-crystalline nylon 1010 cannot be fitted by the Kohlrausch-Williams-Watts formula when the experiments were performed at pre-yielding regime below the glass transition temperature. The instrument can do thermomechanical analysis TMA.

Expected Behavior For Creep Recovery Left And Stress Relaxation Download Scientific Diagram

Creep Relaxation Cracking And Material Properties Youtube

Long Term Polymer Properties Don T Be Creepy Just Relax The Stress Away Ewi

Comments

Post a Comment